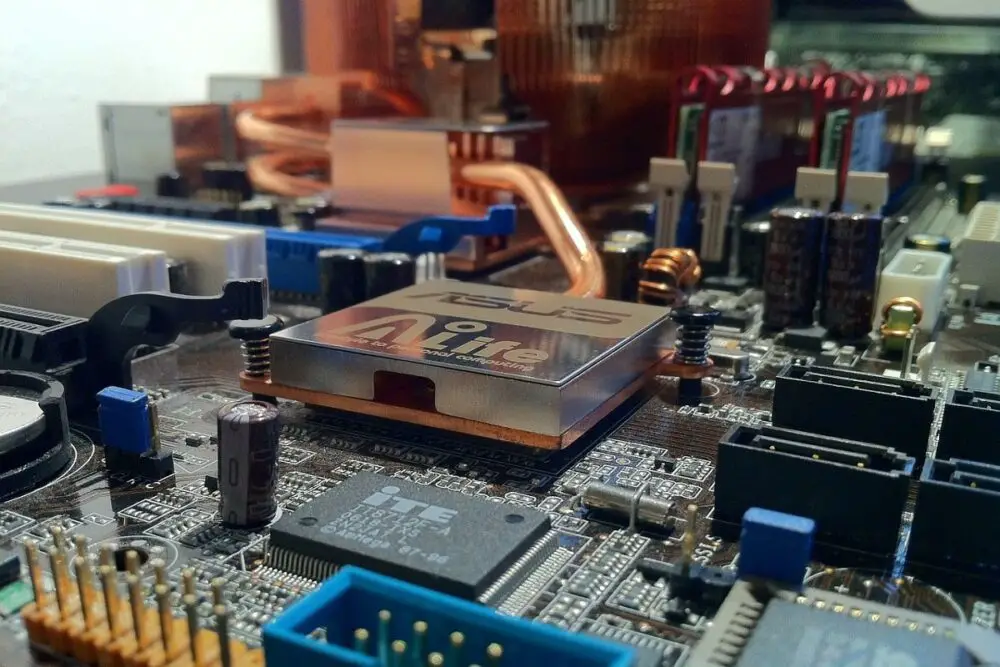

The advancement of technology has seen microchips go from just being used in computers and cars to our common everyday devices. Our electric toothbrushes and dryers now use chips, among so many other products.

Imagine having a problem accessing the latest live casino games because the device you need to use doesn’t have the necessary chip to work. However, it has been observed that the effect of chip shortage is minimal in the online casino industry. The iGaming industry has remained very flexible despite this shortage. However, with the chip shortage expected to last until mid-2022, there’s no telling what direction this could take.

effects of scarcity

One of the effects associated with shortages is that our everyday appliances could be at risk. The production of chips for our washing machines and toothbrushes has been affected. Although, some retailers still have these appliances in stock because they have filled up their warehouses. However, there is a possibility of shortages in the coming months.

The auto industry took the biggest hit. It is based entirely on microchips for driver assistance systems for computerized engine management. At companies like Ford, VW and Jaguar, the effects can be seen as they have closed their factories, laid off workers and reduced production.

This chip shortage has significantly affected most forms of manufacturing, from small businesses to large industries. Most manufacturing machines use microchips to control their functions in the production process. Manufacturing is lagging or not happening at all.

Why the shortage?

- The most direct answer to this question is lack of supply and high demand. The chip shortage is also due to pandemic shutdowns and geopolitics.

The reason for the high demand is a result of the digitization of most systems and processes since 2020. The microchip manufacturing process involves many complexities that require specialized technology to continue production. The shutdown affected the manufacturing industry as well as other industries.

Most manufacturing plants are running at full capacity, but this has proven to be insufficient. Building new factories is expensive and time consuming, and it will take time to get them up and running.

- The automotive industry has seen the most significant increase in demand, with a single modern vehicle needing up to 3,000 microchips for production.

- The gaming and cryptocurrency industry has shown a significant increase in demand as bots and scalpers buy up everything on offer.

- As a result of the pandemic, electronic home and office supplies have also seen a surge in demand as more people are forced to work remotely.

- Chinese companies control about 10% of microchip production. The lockdown and a shortage of shipping containers led to fewer deliveries from China.

- In March 2021, a fire broke out in Japan that destroyed machines at a semiconductor plant that produces about a third of the world’s vehicle microchips.

Solutions to scarcity

In the United States, the Biden-Harris Administration established a task force to address supply chain bottlenecks and create incentives to expand chip manufacturing.

In Canada, the Semiconductor Council established a council in May 2021 to address the microchip issue. Canadians were called upon to look at scarcity and think more strategically by establishing themselves as a leading developer.

Subscribe to our latest newsletter

To read our exclusive content, sign up now. $5/month, $50/year

Categories: Technology

Source: vtt.edu.vn