The 3D printing industry is continuously gaining popularity in different industries. It is true that PETG is one of the most popular 3D printing materials along with ABS and PLA.

Its characteristics make it a desirable 3D printing material. The best thing about digital printing with PETG is that it is not as difficult as you might imagine. Before you learn how to successfully print with PETG, we have prepared vital background information.

You will understand the following by reading this article in its entirety:

- What exactly is PETG?

- What are the advantages and disadvantages of printing with PETG?

- Where can you 3D print models using PETG?

- Top Tips for Using PETG 3D Printing Material

Let us begin!

What exactly is PETG?

PETG (Polyethylene terephthalate glycol) is a PET-based thermoplastic filament, it is a modified version of PET with glycol, hence PETG. PETG is one of the most popular 3D printing materials. In fact, it can be used as an alternative to PLA or even ABS 3D printing thermoplastics. FDM 3D printers mainly use this thermoplastic 3D filament to print high-resolution 3D models.

Various types of petg filament

3D printed models have smooth, shiny surfaces. It is essential to note that PETG is a strong and durable thermoplastic filament with remarkably low shrinkage rates. It has many uses, as you will see later in this article.

The best thing about printing with PETG is that it does not produce strong odors, it is almost odorless. However, the absence of strong vapors does not mean that the vapors produced during printing are safe to inhale.

PETG produces small particles, which are certainly not good for your health. It would be better if you print using PETG in an environment with proper ventilation.

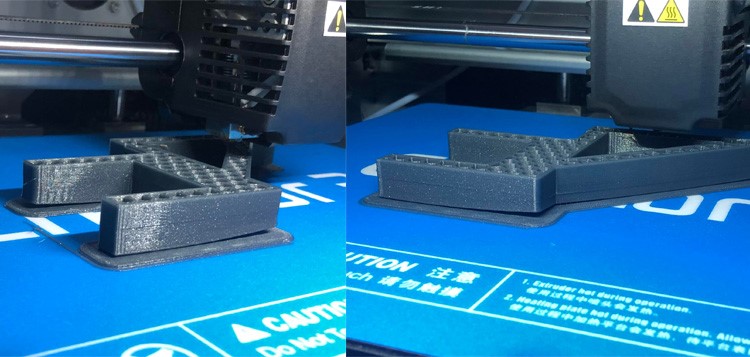

3D printing with PETG filament on a Flashforge 3D printer

3D printing with PETG filament on a Flashforge 3D printer

PETG Thermoplastic Filament Specifications

|

thermoplastic characteristics |

Specifications |

|

Cost |

Cheap |

|

Strength |

Excellent resistance and mechanical abilities. |

|

Flexibility |

Decent flexibility compared to ABS and PLA |

|

dimensional accuracy |

Excellent dimensional accuracy (probability of ± 0.03 mm) |

|

color options |

Wide range of colors, including a transparent option |

|

outdoor performance |

Excellent outdoor performance with high hardness and resistance |

|

Thermoplastic Resistance |

Specifications |

|

Heat resistance |

Excellent resistance to heat, including UV radiation |

|

Waterproof |

decent water resistance |

|

Chemical resistance |

Superior chemical resistance performance compared to other thermoplastic filaments |

|

Impact resistence |

Excellent impact resistance |

|

Fire |

Excellent flame retardant performance |

|

thermoplastic printing |

Specifications |

|

heat bed temperature |

75°C – 90°C |

|

Nozzle temperature (extruder) |

230°C – 250°C |

|

construction surface |

painter’s tape, glue stick |

|

Fan |

Required (at 20% – 50%) |

|

Enclosure |

There’s no need |

What are the advantages and disadvantages of printing with PETG?

advantages

Printing with PETG thermoplastic filament has six main benefits. Look at them:

- High strength, resistance to heat, water, chemicals and impact: PETG has exceptional mechanical resistance, which makes it ideal for printing 3D models in various industries.

In addition, it has excellent resistance to heat and chemicals. The thermoplastic filament has decent water resistance.

- Cost effective – While PETG is more expensive than PLA and ABS, it is still cost effective. It offers high-quality 3D models at an affordable price.

- Almost no odor when printing: Similar to PLA, printing with PETG does not produce strong odors. However, it would be best to avoid inhaling the vapors produced when printing.

- Smooth, Glossy Finish: Printing with PETG produces strong models with smooth, glossy surfaces. In other words, the finish is beautifully aesthetic.

- Multiple Colors Availability – PETG thermoplastic filament has many colors to choose from. These colors also include a transparent option. The multiple color options are beneficial because they allow you to color-code your 3D models.

- Food safe and industrially recyclable: PETG has a chemically neutral reaction towards food material. Therefore, you can print custom plastic plates, water bottles, etc., using this thermoplastic.

Plus, it’s industrially recyclable, which means you’ll need to dispose of it in an environmentally friendly way after use.

A ghost model printed with white petg filament

A ghost model printed with white petg filament

cons

While PETG printing has many benefits, it has three main drawbacks. Look at them:

- PETG is prone to oozing and stringing: PETG has poor bridging characteristics, making it prone to oozing and stringing. You will need to experiment with the bridging and retracting settings.

In addition, the process is more time-consuming: post-processing is necessary to remove all imperfections on the surface of the 3D model.

- PETG has a negative environmental impact when disposed of in an environmentally irresponsible manner. Since PETG is primarily made up of plastic material, it will take years to break down, especially if exposed to marine life.

Luckily, PETG is industrially recyclable. Consider disposing of it after using it in an environmentally responsible manner.

- PETG can become brittle if it doesn’t print well, especially if you don’t pay close attention to the temperature of the heat bed and extruder. Additionally, PETG also becomes brittle after absorbing a significant amount of moisture.

In summary:

|

advantages |

cons |

|

High strength with exceptional resistance to heat, chemicals, water and impact. |

Prone to oozing and skewering. |

|

Economic. |

Negative environmental impact if disposed of incorrectly. |

|

Almost odorless when printing. |

The filament can become brittle due to incorrect printing and significant moisture absorption. |

|

Smooth and shiny finish |

|

|

Wide range of colors to choose from (including a transparent option) |

|

|

Food safe and industrially recyclable |

Which industries benefit most from PETG 3D printing

PETG 3D printed models serve a wide range of industries. Look at them:

- Engineering for rapid prototyping: You can develop functional prototypes by printing with PETG, for example, electronic parts. The best part of using PETG is its excellent dimensional accuracy, which is very important when printing functional prototypes.

In addition, its resistance to heat, chemicals, water and impact are also essential for the engineering industry.

- Food Industry – Since PETG has a chemically neutral reaction with food materials, you can use it to print custom plastic plates or even water bottles.

- Medical Industry: PETG is popularly used in the medical industry to print smooth, shiny, high-quality dental appliances.

- It is used to print packaging for consumer products, for example, liquid soap bottles, cosmetics, snap closures, battery caps, etc.

How can you make 3D printing with PETG successful?

Check out these six best practices for a successful print process when printing with PETG:

- Keep an eye on the print temperature – As you have read earlier in this article, using the wrong temperature will make your PETG 3D model brittle. You need to make sure that the temperature of your printer’s heat bed and nozzle (extruder) is within the recommended range.

- In addition to keeping an eye on the print temperature, it would be best to keep an eye on the speed of the cooling fan. Too much cooling fan speed will cause your PETG model to crack. The ideal speed of the cooling fan should be between 20% and 50%.

- Invest in a good build surface, as PETG requires excellent bed adhesion. Consider using a glue stick or hairspray to improve adhesion, which will help prevent the printed model from peeling off the build surface.

- Keep refractive velocities below 40mm/s as this will help reduce stringing. Strings are fine plastic hairs that run through the 3D model and must be removed after processing.

- It would be better to store your PETG thermoplastic filament in a dry environment because it is hygroscopic. PETG filament will become brittle after absorbing a significant amount of ambient moisture.

- Use a support material to print 3D models with complex geometries. PETG works very well with PVA filaments, a soft, biodegradable support material.

final thoughts

PETG printing is highly beneficial to a wide range of industries. This thermoplastic filament is strong, versatile, and resistant to heat, chemicals, water, and impact. As the 3D printing industry continues to gain popularity, PETG has a bright future.

Consider using the six best practices outlined in this article to make your PETG 3D printing process a success.

Subscribe to our latest newsletter

To read our exclusive content, sign up now. $5/month, $50/year

Categories: Technology

Source: vtt.edu.vn