Understanding inks for bioprinting

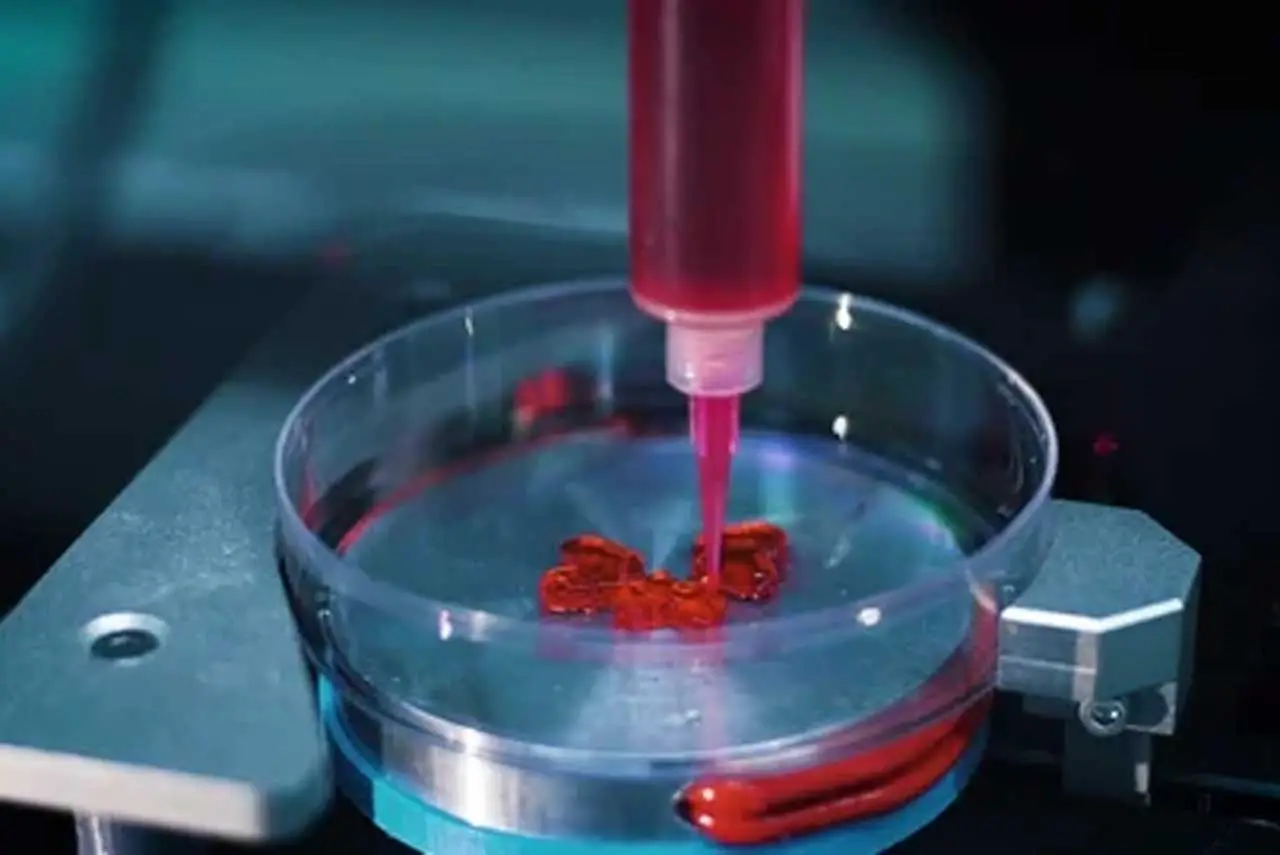

Three-dimensional (3D) bioprinting combines the benefits of developmental biology, stem cells, and 3D printing to combine different biomolecules, biomaterials, and cell types in a predefined position in a printed composite architecture. Bioprinting requires the use of specialized bioprinting inks. 3D bioprinting has taken the study of organ and tissue engineering to the next level and has played an important role in the study of disease pathogens.

What is Bioink?

Bioink is an essential part of the bioprinting process, as it is a mixture of bioactive molecules, cells, and biomaterials to create a 3D printed item.

Bioinks mimic the extracellular matrix (ECM) environment, which promotes cell adhesion, differentiation, and imprint proliferation. To do this, a bioink must contain non-toxic bioactive components that can be modified by intrinsic cells after printing. They should also include gelling conditions or mild crosslinkability and have printing temperatures that do not exceed physiological temperature.

What types of Bioink are available?

There are four main types of 3D bioprinting bioink available, including animal derived to facilitate an adapted scaffold for structural and functional cellular organization. In addition to this, we have natural bioinks which are suitable for various tissue engineering applications possessing unique biodegradability and biocompatibility. Polymer-based bioink it is ideal for physical crosslinking via hydrogen bonding, with medium to high viscosity in solutions based on concentration. Lastly, we have peptide-based bioink, Bioprinting PeptiInks, specially formulated for precise 3D bioprinting to mimic the extracellular matrix with its nanofibrous network for advanced 3D cell culture applications.

bioprinting techniques

Six main bioprinting techniques are currently used. inkjet based Bioprinting allows contactless printing using droplets of dilute solutions dispensed via piezoelectric, thermal, or microvalve printing techniques. Extrusion-based bioprinting It comprises a series of processes and the sequential layer-by-layer delivery to manufacturing objects according to preset computer-aided design data. Another method uses light-reactive thermosetting materials known as Stereolithographic Bioprinting (SLA) exposed to wavelengths of light to join molecular chains and give solidified rigid or flexible geometries. Fused deposition modeling (FDM) is an extrusion printing technique that passes material in the form of a solid filament through a heating tool. The molten filament is then deposited layer by layer to create the CAD-defined pattern. Finally, Selective laser sintering Bioprinting (SLS) uses laser-powered additive manufacturing to sinter powdered material. The laser dots point to spatial points defined by the 3D model, joining the material together as a solid structure.

What benefits are there in the use of Bioinks?

Bio-Inks are the easiest way to gain precise control over crafted buildings. They offer high performance, consistent reproducibility, and cost-effectiveness. Bioinks are one of the most advanced tissue engineering and regenerative tools available for 3D bioprinting. While they are functional and not harmful to living tissue, they are not translatable or scalable in the same way as synthetic peptide bioinks. Choosing a bioink that is fully synthetic and has tailored mechanical and functional properties that are completely reproducible to closely mimic all tissue types can avoid the significant batch-to-batch variations associated with natural bioinks.

Conclusion

The bioprinting process chosen among those mentioned above will depend on the type of bioink selected, which depends on the complexity of the final tissue structure. Selecting the most suitable bioink requires you to be aware of and aware of the bioinks ability to control the formation of defined droplets and their morphology and fidelity to the deposited building blocks.

Also, how compatible is the bioink with living cells and living tissue. It is also essential to identify the likelihood of bioinks producing toxic or immunological reactions when exposed to the body or body fluids in use. You should also consider whether the inherent property of 3D printing will change from solid to gel and remain intact when exposed to certain physiological conditions or is likely to break down upon exposure to microorganisms. A bioink with viscoelasticity provides better tissue formation, and shear thinning bioinks can be used with extrusion-based printers, as bioink viscosity decreases under shear stress.

Apart from this, you can also read articles related to entertainment, technology and health here: Goku Kung Fu Panda 4 Leonardo DiCaprio Net Worth Diabolik Lovers Season 3 Twitch Error 2000 Alyson Hannigan Brent Net Worth Rivera, Emma Watson net worth, angel number 444, angel number 666, angel number 1616, angel number 777, angel number 333, Dave Portnoy net worth, Lionel Messi net worth, Keanu Reeves net worth, The Equalizer 3, The 100 Season 8, Gina Carano Network Bruno Mars Net Worth, KissAnime, Jim Carrey Net Worth, PDF Drive, Youtbe, Bailey Sarian Net Worth, Bollyshare, Afdah, Moviezwap, Y8, Jalshamoviez, Project Free TV, Kissasian, Mangago, Jio Rockers, M4uHD, Hip dips, M4ufree, NBAstreams XYZ, CCleaner browser review, Avocado Calories, Bear Grylls net worth, Highest paid CEO, The 100 season 8, Sundar Pichai net worth, net worth by Grimes and F95Zone.

Subscribe to our latest newsletter

To read our exclusive content, sign up now. $5/month, $50/year

Categories: Technology

Source: vtt.edu.vn