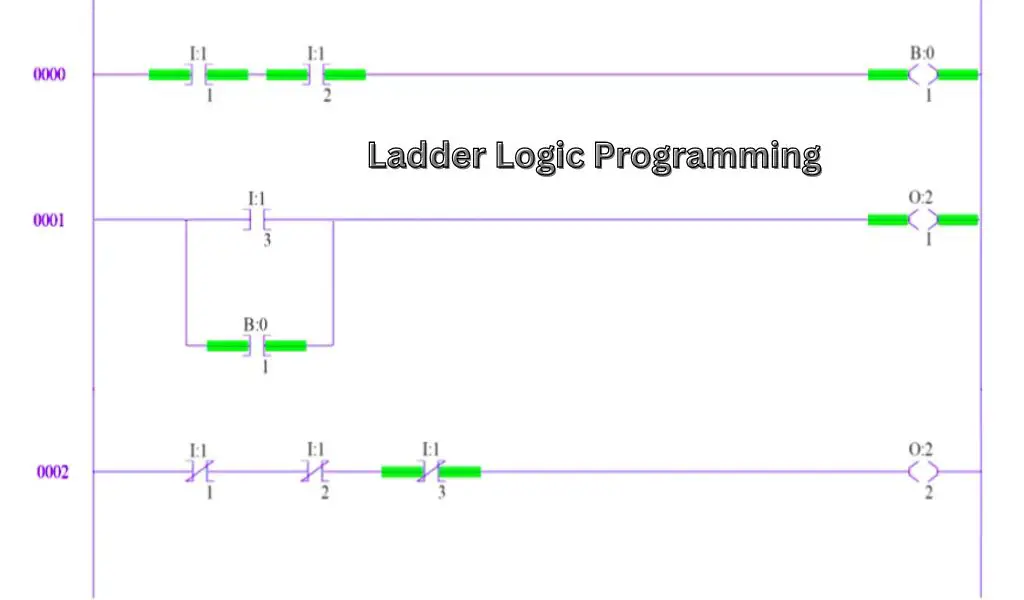

Ladder logic programming is a programming language based on circuit diagrams. Programmable Logic Controllers (PLCs), which are used in industrial applications, are the main target audience.

Since each relay rack is represented by a symbol in the ladder diagram with connections to devices below it that resemble vertical rails, the language has evolved from being a way to describe the design and construction of relay racks. used in manufacturing and process management. The relay symbols resemble the rungs of a ladder.

Ladder Logic Programming Application Scenarios

In ladder logic programming, each system in the relay rack will have a symbol indicating the relationships between the various devices. The ladder schematic will also include additional items beyond the relay rack, such as pumps, heaters, etc.

- Relay logic hardware circuit diagrams have evolved into the ladder logic programming language, which describes a system through a graphical representation.

- Industrial control applications employ ladder logic, which is used to create software for programmable logic controllers (PLCs).

- Ladder logic is useful for redesigning outdated hardwired relay circuits, as well as for simple but crucial control systems.

- Due to the advancement of programmable logic controllers, this has also been used in highly sophisticated automation systems. Rather than being a procedural language, ladder logic should be thought of as a rules language. A rule is represented as a “rung” of a ladder.

Strengths of Using Ladder Logic Programming

Self-documenting and intuitive: A ladder diagram provides an effective graphical representation of circuit design principles. The learning curve to start using a ladder diagram is quite low due to the familiarity of the environment; Fundamental programming skills emerge quickly. Because of this, the ladder diagram is especially appreciated by applications that require employees without knowledge of software to debug or maintain them, such as some electricians or plant technicians.

Great debugging tools: A ladder diagram with contemporary internet debugging tools provides an animation of a live “flow of energy”. This makes it very easy to understand the logic of the diagram and to track down any errors.

Discrete logical representation that is effective: A ladder logic program makes sense to illustrate discrete logic because it is made to look like electrical circuits. A ladder diagram is almost intuitive for digital logic.

Benefits of Using the Ladder Logic Programming Language

A Ladder Logic Programming provides an excellent schematic interpretation that focuses on well-known circuit architecture principles. Due to the accessibility of the environment and the low learning curve required to get started with a ladder diagram, basic programming skills develop quickly. Ladder logic programming has been particularly popular in applications involving personnel with no technical background to manage or repair, such as dedicated electricians or plant specialists. Since the programming language is designed to represent electrical circuits, it is ideal for expressing abstract logic. For digital logic, the language is quite simple to understand.

Get the best result with ladder logic programming

When operations and production processes need to be controlled sequentially, ladder logic is frequently used in industrial settings to program PLCs. The programming language is very useful for creating new programmable versions of older hardwired systems or for creating basic but crucial systems. Much of this programming language is also used in extremely complex automation systems, including those in electronics and automobile manufacturers.

The premise behind ladder logic is that because it uses common and well-known technical symbols for programming, even employees with no programming experience can program quickly. However, this benefit is quickly lost because PLC manufacturers often include ladder logic programming systems with their products. These systems often do not use the same symbols and conventions as those created for other manufacturers’ PLC models; in fact, the programming system is usually designed for specific models only, making porting existing programs to other PLC models difficult or requiring a complete rewrite.

Subscribe to our latest newsletter

To read our exclusive content, sign up now. $5/month, $50/year

Categories: Technology

Source: vtt.edu.vn